Understanding the Synthesis of Linear–Bottlebrush–Linear Block Copolymers: Toward Plastomers with Well-Defined Mechanical Properties

Abstract

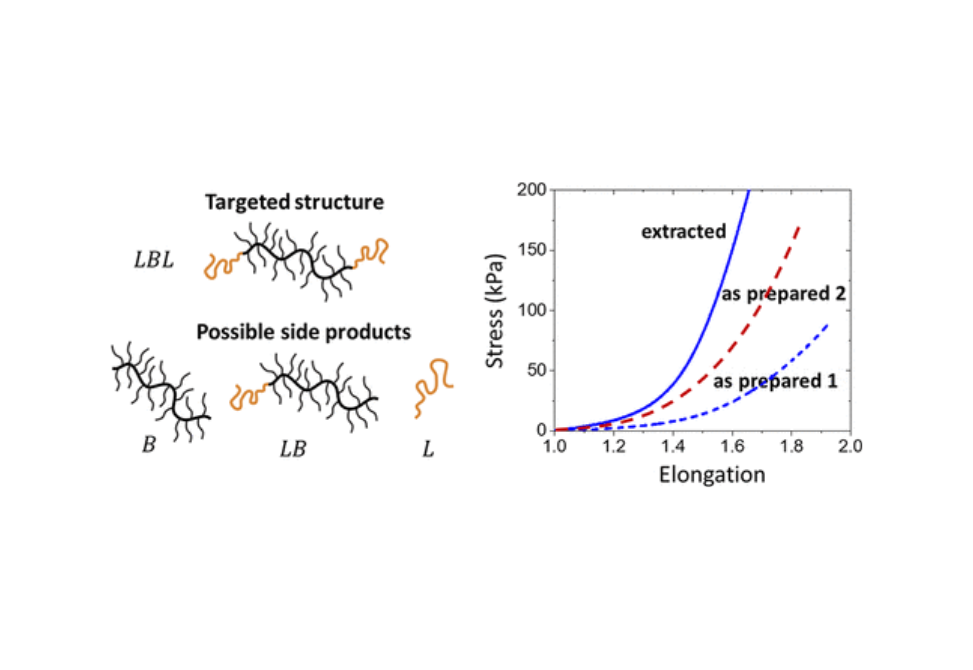

Linear–bottlebrush–linear (LBL) triblock copolymers were synthesized via a two-step atom transfer radical polymerization (ATRP): (i) grafting-through polymerization of monomethacryloxypropyl-terminated poly(dimethylsiloxane) (PDMS11MA) macromonomers, which yielded difunctional P(PDMS11MA) bottlebrush macroinitiators, followed by (ii) the growth of linear poly(methyl methacrylate) chains at both ends of the bottlebrush backbone. Upon microphase separation, LBL triblock copolymers self-assembled into thermoplastic elastomers (plastomers) that exhibited tissue-like mechanical properties controlled by triblock composition and architecture. The mechanical properties of plastomers obtained from different synthetic batches initially demonstrated variability due to the deleterious termination of chain ends, resulting in undesired side products, consisting of linear–brush diblocks and bottlebrush monoblocks in the final product. Therefore, the kinetics of grafting-through polymerization of PDMS11MA macromonomers was studied to establish correlations between reversible first-order kinetic trends and network mechanical properties. By varying the reaction conditions, including the initial monomer concentration, targeted degree of polymerization, and solvent, the syntheses of macroinitiators and chain extensions were optimized with improved chain-end fidelity while maintaining a high yield and provided elastomers with consistent desired mechanical properties.

Citation

Understanding the Synthesis of Linear–Bottlebrush–Linear Block Copolymers: Toward Plastomers with Well-Defined Mechanical Properties

Yidan Cong, Mohammad Vatankhah-Varnosfaderani, Vahid Karimkhani, Andrew N. Keith, Frank A. Leibfarth, Michael R. Martinez, Krzysztof Matyjaszewski, and Sergei S. Sheiko

Macromolecules 2020 53 (19), 8324-8332

DOI: 10.1021/acs.macromol.0c01083