UNC Researchers Use Chemical ‘Glue’ to Power Solar Fuel Breakthrough

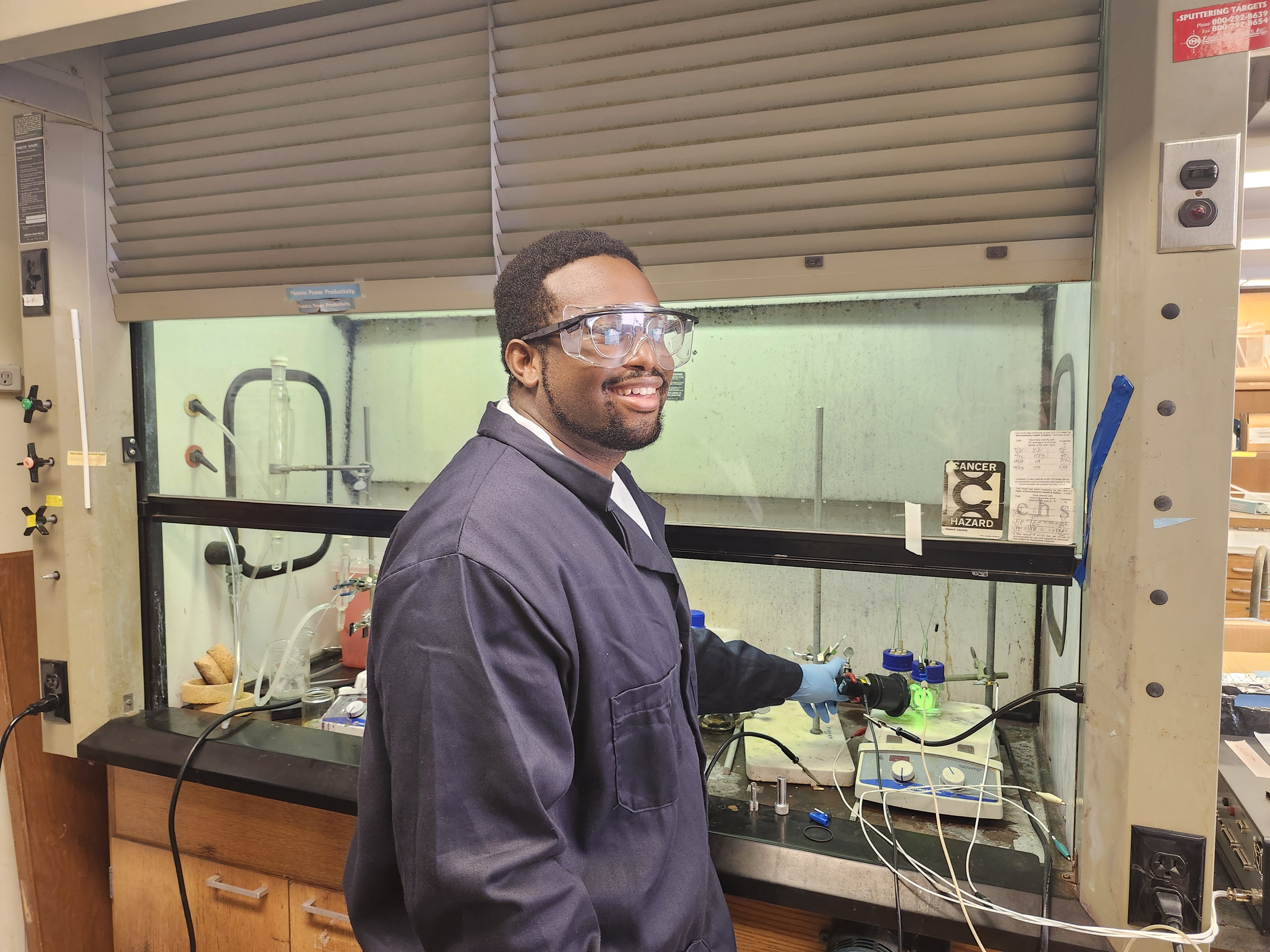

Andre Orr, a Ph.D. candidate in the Department of Chemistry, is the lead author of a study supported by the Department of Energy-funded Center for Hybrid Approaches in Solar Energy and Liquid Fuels (CHASE) that attempts to tackle a big question: How do we capture and use sunlight to recycle carbon dioxide, a major greenhouse gas, into value-added products and fuels?

June 27, 2025 I By Dave DeFusco

In a step toward a cleaner energy future, UNC-Chapel Hill chemistry researchers have discovered a new way to attach powerful carbon dioxide-reducing molecules to silicon surfaces that could help scientists harness sunlight to turn carbon dioxide into useful fuels and chemicals—essentially storing solar energy in liquid form.

Supported by the Department of Energy-funded Center for Hybrid Approaches in Solar Energy and Liquid Fuels (CHASE), the research team tackled a big question in the ACS Applied Materials & Interfaces study, “Immobilizing a Lehn-Type Catalyst with Nitrocyclocondensation Chemistries: CO2 Reduction on Silicon Hybrid Photoelectrodes”: How do we capture and use sunlight to recycle carbon dioxide (CO₂), a major greenhouse gas, into value-added products and fuels?

To turn sunlight and carbon dioxide into fuel, researchers at CHASE are building special surfaces where materials like silicon can absorb sunlight and create the electricity needed to power chemical reactions. These reactions are helped along by tiny molecules called catalysts, which turn CO₂ into useful fuels. But there’s a challenge. Those catalysts don’t easily stay attached to the silicon. The UNC team found a way to fix that using a special chemical “glue” made through a reaction called nitrocyclocondensation (NCC). This glue not only keeps the catalyst stuck to the silicon during the reaction, but also makes sure electricity can flow smoothly between the two, helping the system work more efficiently.

“Attaching molecules to silicon in a way that survives the harsh conditions needed to reduce CO₂ has always been a challenge,” said Andre Orr, first author of the study and a Ph.D. chemistry student working in the laboratories Professors James Cahoon and Matthew Lockett. “Many previous attempts had limited stability or weren’t flexible enough to incorporate different kinds of molecular catalysts.”

Their method borrows from earlier studies that used NCC reactions to bind molecules onto silicon in highly controlled lab environments, like ultrahigh vacuum chambers. Until now, no one had shown that NCC chemistries were suitable for the conditions needed to generate solar fuels, e.g., immersed in a liquid under illumination with sunlight.

“We took that chemistry and applied it in solution, meaning we can now we can perform NCC reactions at a much more practical scale,” said Orr.

Silicon is the same material used in most solar panels. It’s cheap, abundant and great at absorbing sunlight. The clean surface needed for attaching molecules is highly reactive, easily forming a thin insulating layer, silicon oxide, that cannot efficiently transfer energy from the material to the attached catalyst.

To prepare their modified photoelectrodes, which are special materials that use light to generate electricity and drive chemical reactions, freshly cleaned silicon was placed in a special liquid that promoted the NCC reaction, forming strong nitrogen-silicon bonds. They demonstrated the utility of the NCC reaction on two very different molecules: A redox reporter molecule—a kind of electrochemical indicator to track reaction completion on the surface and the ability of the newly formed interface to transfer electrons from silicon to the attached molecules

A CO₂-reduction catalyst based on a metal called rhenium, known for turning CO₂ into carbon monoxide, a key building block for fuels and industrial chemicals.

Under artificial sunlight, their catalyst-coated silicon converted CO₂ into carbon monoxide with 23% efficiency, a performance that outshines similar systems prepared with other methods.

“This work gives researchers a toolkit for making more durable and efficient solar fuel devices,” said Dr. Matthew Lockett, senior author of the study and an associate professor in the UNC Department of Chemistry. “The real impact is that it opens the door to attaching many kinds of catalysts in a much simpler way.”

That flexibility is important because different catalysts can make different products—not just carbon monoxide, but potentially methane, ethylene, alcohols or even jet fuel.

“The ability to mix and match catalysts and surfaces with this technique could help us custom-build solar reactors to fit a wide range of liquid energy needs,” said Lockett.

The UNC team is now exploring how to improve the amount of catalyst that can be packed onto the surface, test more complex catalysts that produce richer chemical products and scale the process for larger solar devices.

“We’re just scratching the surface—literally,” said Orr.