Next Time You Crack Open a Cold One, Forever Chemicals Could Be Lurking, Researcher Warns

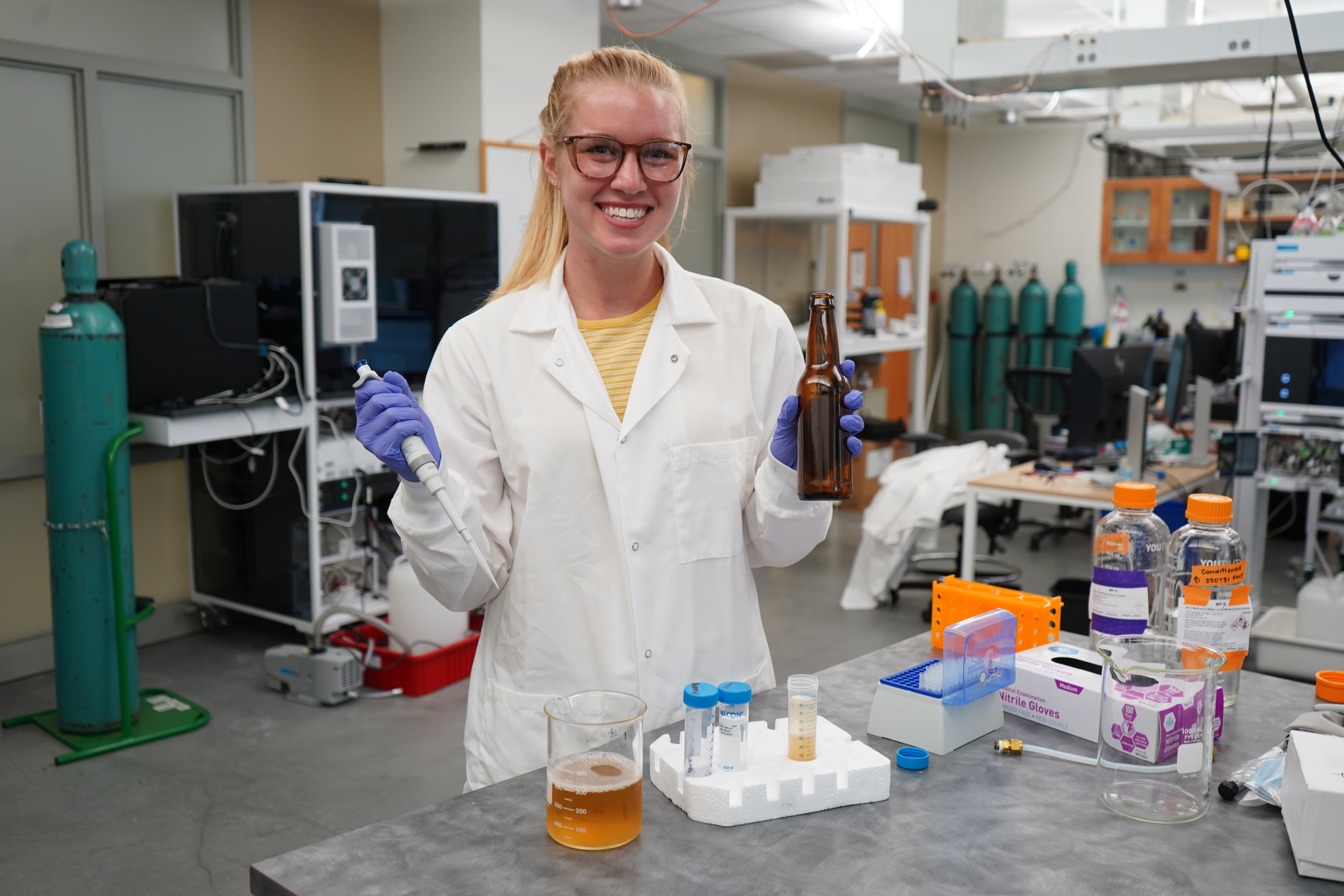

Ashlee Falls, a Ph.D. student in the Baker Lab, is focusing on how to optimize methods for extracting and quantifying forever chemicals in beer so that researchers and brewers can better understand how much of these chemicals are making it from water and ingredients into the final product.

August 23, 2025 | By Dave DeFusco

When you crack open a cold beer, you might think about hops, barley or yeast, but probably not “forever chemicals.” Yet these synthetic substances, known as PFAS (per- and polyfluoroalkyl substances), may be hiding in your drink, and Carolina scientists are figuring out how to detect them.

PFAS are a large family of chemicals prized by manufacturers for being water- and oil-resistant. They’ve been used in everything from nonstick pans to waterproof jackets. The downside is that PFAS don’t easily break down in nature or in our bodies. Over time, they’ve spread into drinking water, soil and even rainfall. Studies have linked them to serious health problems, including high cholesterol, weakened immune systems, certain cancers and low birth weight.

“More than 99% of people have PFAS in their blood,” said Ashlee Falls, a Ph.D. student in the Baker Lab in the Department of Chemistry. “That means our exposure is happening in more ways than we realize, and beverages like beer could be one of those pathways.”

Falls recently presented her work at the American Society for Mass Spectrometry (ASMS) conference, focusing on how to accurately measure PFAS in beer brewed around the world. Her project aims to optimize methods for extracting and quantifying PFAS so researchers and brewers can better understand how much of these chemicals are making it from water and ingredients into the final product.

“Ashlee is very interested in water quality and how water contamination affects human health,” said Dr. Erin Baker, an associate professor and Falls’ Ph.D. advisor. “Her desire to increase health and help brewers create the best products possible inspired Ashlee to design the PFAS beer study and push through all the measurement difficulties she has encountered to date.”

Beer is mostly water, or about 95% by volume. If local water supplies contain PFAS, there’s a good chance they could make it into your pint. The challenge is that most breweries don’t currently test for PFAS, and current methods are not optimized for dark beers like porters or stouts.

Testing is further complicated by beer’s chemistry. Unlike plain drinking water, beer contains carbonation, proteins, sugars and other compounds from grains, hops and yeast. These extras can get in the way of detecting PFAS in the lab.

“Beer is a really complex liquid,” said Falls. “When you’re trying to measure tiny amounts of PFAS, all those other ingredients can interfere with the analysis.”

To tackle the problem, Falls tested three variations of a lab process called QuEChERS, pronounced catchers, a method widely used to extract pesticides from food. She used special chemical cartridges designed to remove fats, sugars or both from beer before analyzing it. The idea was to clean up the beer sample just enough so that any PFAS present could be detected using high-tech approaches, such as combining liquid chromatography, ion mobility spectrometry and mass spectrometry (LC-IMS-MS) separations.

In her trials, she first spiked beer samples with known amounts of PFAS to see how much she could recover. The results weren’t encouraging; current methods either didn’t remove those pesky “other ingredients” or they did remove them along with the PFAS. This meant that for the PFAS put into the beer at the beginning, only about 10-15% was observable at the end, far below the ideal 100% recovery rate.

The takeaway is that the usual tools for extracting PFAS from foods and water don’t work well for beer. “Our current methods just aren’t efficient enough,” said Falls. “We need to keep refining them.”

Falls and her colleagues are now testing a new solid phase extraction cartridge designed specifically for pulling PFAS out of complex liquids. Using an automated system, they hope to boost recovery rates to at least 75%, enough to reliably detect PFAS at very low concentrations.

Once the method works well, the team plans to analyze a wide range of beers—lagers, ales, sours and more—from breweries in North Carolina and around the world. That data will help them figure out how PFAS levels vary by region; whether the contamination comes mainly from water, grains or hops; and how brewing practices might influence PFAS levels. The ultimate goal is practical: give brewers an easy, low-cost way to test for PFAS and reassure consumers about what’s in their beer.

While most people think of PFAS as a problem in tap water, Falls says beverages like beer are part of the bigger picture of everyday exposure. “Brewers take pride in the quality of their ingredients and the taste of their beer,” she said. “If PFAS are making their way into the brewing process, that’s something both brewers and consumers deserve to know.”

Her work could also help public health researchers map PFAS contamination worldwide, using beer and other drinks as a snapshot of local water quality.

“We want to make PFAS testing more accessible,” she said. “Whether it’s beer, soda or spirits, our methods could give communities another tool for understanding and eventually reducing their exposure to these chemicals.”