Chemists Use Light and Cobalt to Make Greener, Cheaper Industrial Chemicals

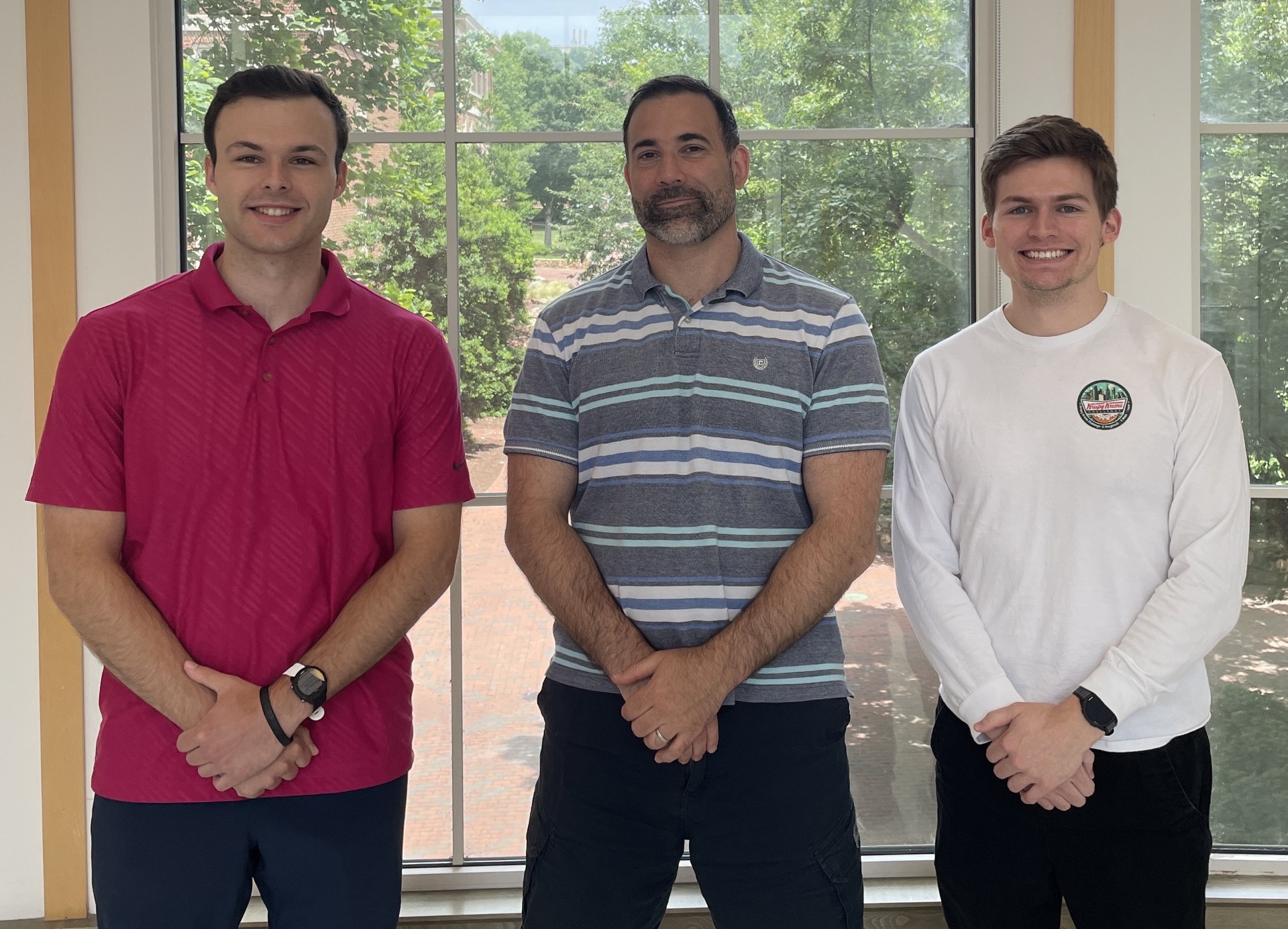

Left to right, Michael Rodriguez, Professor Erik Alexanian and Mason Faculak developed a new method for producing two valuable classes of chemicals—esters and carboxylic acids—which show up in everything from food additives to synthetic textiles and biodegradable materials. Using visible light and a cheap, earth-abundant metal catalyst—cobalt—their process is not only more mild and environmentally friendly but efficient enough for large-scale use, possibly paving the way for cleaner manufacturing of vital chemicals.

May 26, 2025 I By Dave DeFusco

Simple molecules called alkenes—commonly produced during oil refining—are an abundant and low-cost starting point for making a wide range of industrial and consumer products, from fuels and plastics to fragrances and pharmaceuticals. Two particularly valuable classes of chemicals are esters and carboxylic acids, which show up in everything from food additives to synthetic textiles and biodegradable materials.

While these compounds can be made through various well-established methods, converting alkenes into esters and acids is especially appealing because it offers a direct route from cheap feedstocks. However, this type of transformation, known as alkene carbonylation, typically requires rare metals, high heat and extreme pressure, making it costly and difficult to scale. The challenge has been finding a milder, more sustainable way to carry it out.

In a recent Journal of the American Chemical Society study, Mason Faculak and Michael Rodriguez, UNC Ph.D. chemistry students in the lab of Professor Erik Alexanian, developed a new method to produce esters and carboxylic acids using visible light and a cheap, earth-abundant metal catalyst: cobalt. Their process is not only more mild and environmentally friendly but efficient enough for large-scale use, possibly paving the way for cleaner manufacturing of vital chemicals.

“We’re taking a method that’s been around for decades and modernizing it for a sustainable future,” said Faculak, a lead author of the study. “The exciting part is, we’re doing it with materials and conditions that are much more practical and accessible for industry and academia.”

The chemical reactions at the heart of this study—called alkoxycarbonylation and hydroxycarbonylation—turn simple oil- and gas-based molecules known as alkenes into more useful ones like esters and carboxylic acids, which are widely used in products from plastics to pharmaceuticals. Traditionally, doing this requires rare and expensive metals like palladium or platinum, extremely high heat (over 250°F) and carbon monoxide gas at pressures more than 40 times what we experience at sea level. In other words, it’s costly, energy-intensive and hard to scale up for industrial use.

The UNC team, however, figured out how to carry out these reactions using cobalt carbonyl—a cheap and abundant metal catalyst—under low pressure and mild temperatures using visible light as a source of energy.

“Using light, instead of heat, to drive this reaction allows it to be more selective with respect to chemical reactivity and also compatible with more complex molecules,” said Rodriguez, the other lead author of the study.

Cobalt by itself wasn’t enough to make the reaction work, so the researchers came up with a smart workaround: they added two simple helper molecules to activate the cobalt. One of them, called DMAP, helped swap out certain parts of the reacting molecules, while the other, triethylammonium tosylate, helped manage the balance between acidic and basic conditions—an important part of keeping the reaction on track.

“Through judicious choice of co-catalysts, we developed a system that is incredibly efficient,” said Rodriguez. “In some cases, with these optimized conditions, we observed yields approaching the theoretical maximum.”

The reaction, as it turns out, also works without any added solvent in some cases, which dramatically cuts down on chemical waste and gives it an exceptionally low E factor—a common measure of environmental impact in industrial chemistry.

The UNC team tested their method on dozens of different alkenes and alcohols, including simple industrial feedstocks, complex molecules like cholesterol and quinine, and natural product derivatives like menthol and proline. These all reacted cleanly under their mild conditions, contrasting with previous methods under which complex molecules might decompose.

“We were happy to see how broad the method was,” said Faculak. “We could pair complex alcohols with complex alkenes and still obtain excellent yields and selectivity.”

Because the process only requires one molecule of alcohol per molecule of alkene, rather than large excesses, it produces less waste and thus is more practical for complex synthesis, key traits for making medicines or fine chemicals, where material costs are high. Professor Alexanian, senior author of the study, said the team’s work represents a major step toward making greener, more scalable chemical reactions.

“This research shows that you don’t need expensive catalysts or extreme conditions to make valuable products on large scales,” said Alexanian. “By using visible light and earth-abundant cobalt, we’re developing methods that enable new reactivity and could help reshape the way essential chemicals are manufactured, especially as industries look to cut costs and reduce their environmental footprint.”