New Sun-Powered Reactor Makes Carbon Dioxide Recycling Cheaper and More Efficient

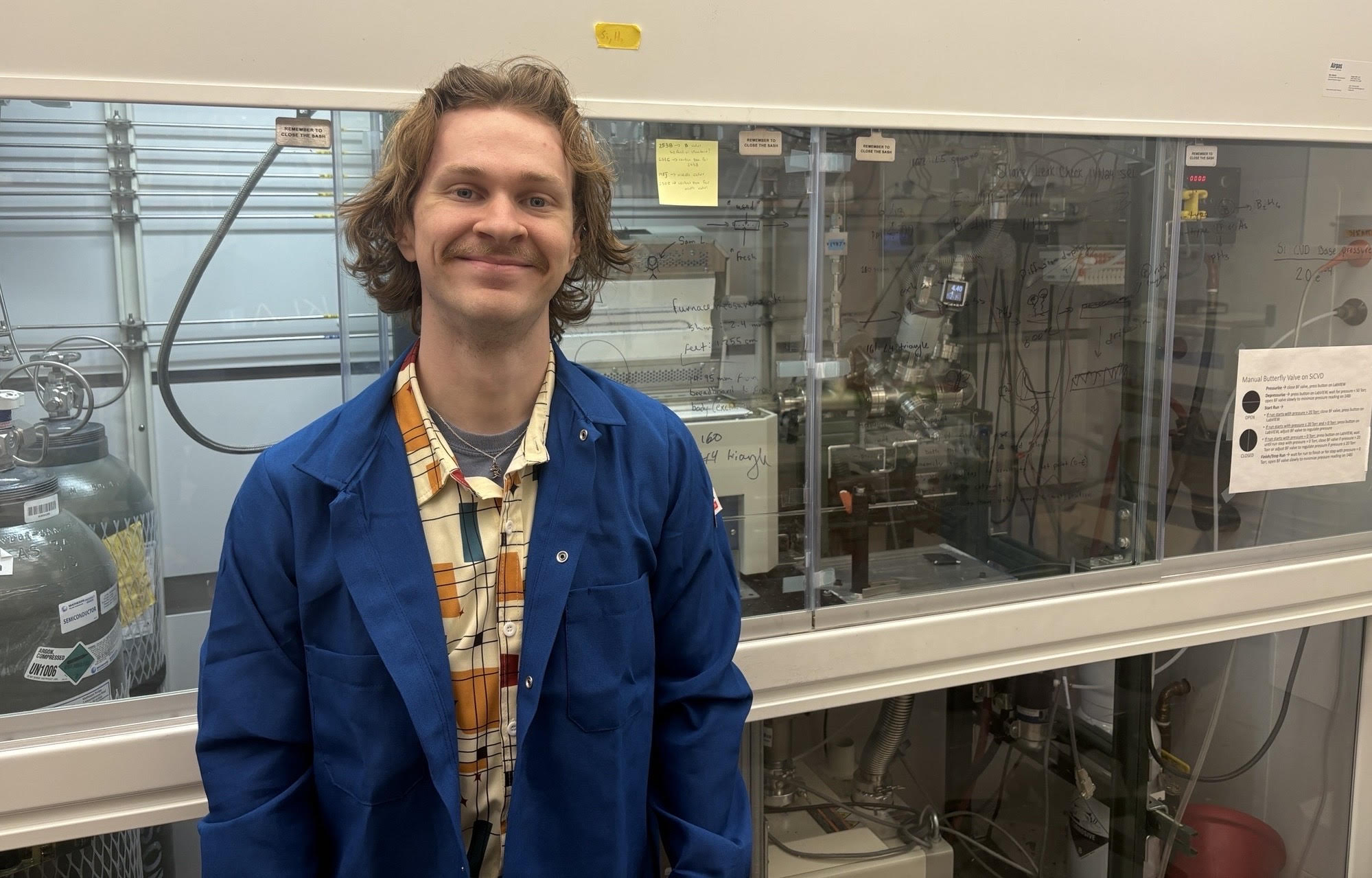

At the 2025 Carolina Science Symposium, Will Hemmingson, a Ph.D. student in the Department of Chemistry, presented his team’s latest work: a particle suspension reactor that uses sunlight, silicon nanowires and clever chemistry to make carbon dioxide reduction more efficient, affordable and durable than previous designs.

November 14, 2025 I By Dave DeFusco

When William Hemmingson came to UNC-Chapel Hill for his Ph.D. in materials chemistry, he joined a lab tackling one of the biggest environmental challenges of our time: finding practical ways to recycle carbon dioxide, the gas most responsible for climate change.

In the Cahoon Lab, led by Professor James Cahoon, Hemmingson and his colleagues are developing a solar-powered chemical system that can transform CO₂ into useful fuels such as methane, methanol and ethanol. Their goal is to someday capture carbon emissions from factories and turn them into clean energy—literally converting waste into power.

At the 2025 Carolina Science Symposium, Hemmingson presented the team’s latest work: a particle suspension reactor that uses sunlight, silicon nanowires and clever chemistry to make CO₂ reduction more efficient, affordable and durable than previous designs.

For years, scientists have tried to mimic photosynthesis, the process by which plants use sunlight to convert carbon dioxide into energy-rich molecules. Most research has focused on flat solar cell reactors that are costly to build and difficult to scale up. Hemmingson and his team took a different approach. Instead of using a rigid solar panel, they created a liquid-filled reactor containing millions of microscopic silicon wires that can move freely and react with CO₂ dissolved in water.

“The particle suspension reactor isn’t entirely new,” said Hemmingson. “It’s been used before for splitting water into hydrogen and oxygen, but not for CO₂ reduction. What’s unique about our design is that our nanowires can generate very high voltages, enough to power more demanding chemical reactions.”

Those high voltages are crucial. The reaction that converts carbon dioxide into fuel needs at least 1.5 volts of energy to get started. Hemmingson’s nanowires can reach up to 10 volts, providing plenty of power for the job. The reactor looks simple, essentially a transparent bag filled with a cloudy suspension of nanowires, but it’s surprisingly effective. Each nanowire absorbs and scatters sunlight, and together they trap nearly all of the incoming light.

“When the particles are this small,” said Hemmingson, “they actually absorb and scatter light over an area larger than themselves. With millions of them suspended in liquid, the mixture becomes almost opaque, which means it’s capturing most of the sunlight.”

Because the nanowires are surrounded by liquid instead of attached to a flat surface, reactants can reach them more easily, increasing the rate of chemical reactions. While particle suspension reactors have been shown, at least in studies of water splitting, to be less efficient overall than their flat, planar counterparts, they are far more efficient per dollar, making them a practical and scalable option for solar-driven CO₂ reduction. The team also tailors the nanowires’ surfaces with metal co-catalysts and thin polymer layers that control what products are formed.

“Changing the metal catalyst changes everything,” said Hemmingson. “Platinum helps make hydrogen gas, but copper can produce higher-value products like ethanol or ethylene, which are useful as fuels or building blocks for plastics.”

Copper’s drawback is that it tends to produce a wide mix of products rather than one specific compound. To help with that, the researchers add a thin polymer coating that modifies the chemical environment near the surface of the wire, steering the reaction toward more desirable products.

In initial tests, the reactor achieved an apparent quantum yield of 5.8% for hydrogen, 0.7% for methane and 0.9% for carbon monoxide—a measure of how efficiently sunlight is converted into chemical energy. It’s an impressive number for an early-stage prototype. The system has produced a variety of carbon-based products, including hydrogen, methane, carbon monoxide, formic acid, methanol and methyl acetate, showing its versatility.

“One of our current challenges is consistency,” said Hemmingson. “Some nanowires produce slightly different voltages or efficiencies. If we can make each one perform the same way, we can push the yield even higher.”

The design also offers practical advantages. In traditional flat reactors, a single defect can damage the entire system. In the particle suspension reactor, millions of nanowires work independently so if a few break, the rest continue operating. “That makes the whole setup more robust and reliable,” he said.

Hemmingson credits much of the project’s success to the collaborative culture in the Cahoon Lab. “Jim is an incredible PI,” he said. “He’s deeply knowledgeable and genuinely excited about the science. That enthusiasm spreads through the group.”

The lab brings together chemists, engineers and physicists, each contributing a different skill set—from growing nanowires in custom-built reactors to studying how light and charge move through them. One major advance came from a former student who designed nanowires capable of generating up to 10 volts, opening the door for new chemical transformations. Though the research is still at a laboratory stage, Hemmingson believes this approach could play a role in carbon-neutral fuel production in the future.

“There’s still a lot of work to do,” he said. “But we’re the first group to explore this reactor design for CO₂ reduction, and that gives us a new direction to pursue. If we can refine the chemistry and scale it up, this could help close the carbon loop by turning emissions into energy instead of pollution.”